How to Choose a Vacuum Defoaming Mixer for Battery Electrode Slurry

Upload Time:

Jul 10, 2025

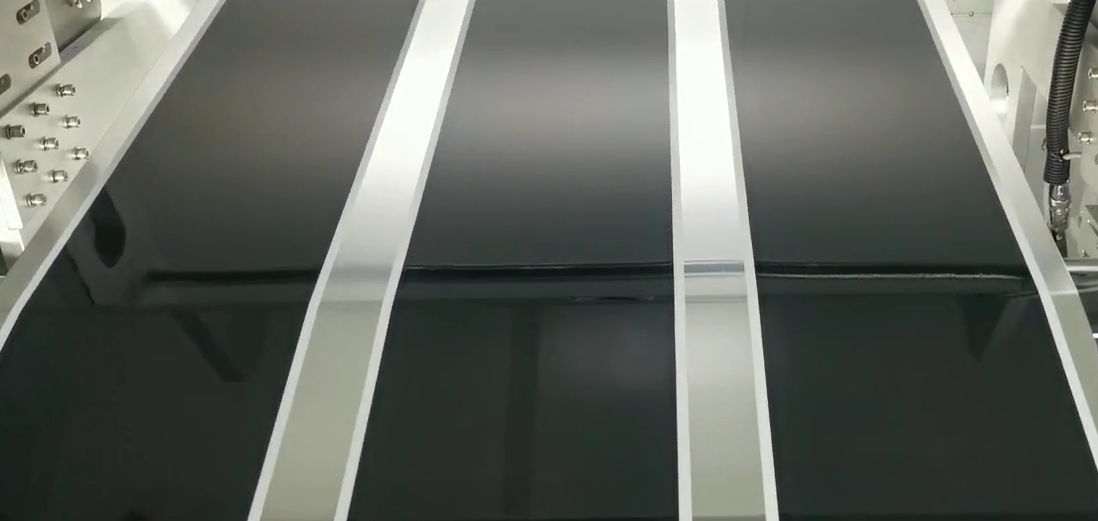

How to Choose a Vacuum Defoaming Mixer for Battery Electrode Slurry,Battery electrode slurry (anode/cathode) demands perfect homogeneity, zero bubbles, and particle integrity to prevent coating defects and cell failure. Here’s how to select the right mixer:

1. Core Technical Parameters: Battery Slurry Edition

-

Vacuum Level & Stability:

-

Target ≤ 0.5 kPa absolute pressure to remove micro-bubbles trapped in viscous slurries.

-

Low leakage rate (< 0.3 kPa/hour) ensures stable vacuum during long mixing cycles (critical for NMP/PVDF-based cathodes).

-

-

Mixing Mechanism:

-

Planetary + Dual-Axis Mixing (Rotation + Revolution): Prevents particle agglomeration (e.g., graphite/SiOx anodes) while ensuring uniform conductive additive (CNT, carbon black) dispersion.

-

Speed Range: 10–100 rpm (low-shear) for active material preservation; 500–3,000 rpm (high-shear) for binder dissolution.

-

-

Capacity:

-

Pilot Lines: 1–5 L (e.g., BL-1000).

-

Mass Production: 50–200 L (e.g., BL-20000).

-

2. Material Compatibility: Battery-Specific Upgrades

-

High-Viscosity Pastes (≥ 50,000 cP):

-

Requires > 400G centrifugal force to homogenize thick cathodes (NCM/LFP + PVDF).

-

Scraper blades prevent dead zones in corners.

-

-

Corrosive Solvents (NMP, DMF):

-

316L stainless steel chamber + PTFE-coated seals to resist chemical degradation.

-

-

Shear-Sensitive Particles:

-

Programmable ramping profiles to gently mix fragile materials (e.g., silicon oxide anodes).

-

3. Efficiency & Battery Production Workflow

-

Continuous Processing:

-

Closed-loop feeding systems for solvent recovery (NMP) and dust-free operation.

-

Throughput: ≥ 50 kg/hour for GW-scale factories.

-

-

Slurry Consistency:

-

Real-time viscosity monitoring sensors to maintain target rheology.

-

4. Critical Smart Features

-

Precision Temperature Control (±1°C):

-

Prevents binder gelation (PVDF) or solvent evaporation during mixing.

-

-

Explosion-Proof Design:

-

ATEX-certified motors/vacuum pumps for flammable solvents (NMP).

-

-

Data Logging:

-

Records RPM, vacuum, temp, and torque for QC traceability (ISO 9001).

-

5. Industry Validation

-

Case Study:

A top-5 battery maker reduced coating defects by 90% using a dual-planetary mixer with 0.3 kPa vacuum and PTFE lining. Slurry stability exceeded 72 hours.

Selection Checklist for Battery Engineers

-

Define Slurry Properties:

-

Solvent type (aqueous/NMP), solid content (60–80%), target viscosity.

-

-

Prioritize Mixing Integrity:

-

Low-shear planetary mechanics + vacuum stability.

-

-

Demand Chemical Resistance:

-

316L SS/PTFE construction for NMP slurries.

-

-

Verify Production Readiness:

-

Throughput, solvent recovery, and CIP (clean-in-place) compatibility.

-

-

Test with Real Slurry:

-

Trial metrics: deaeration rate, particle uniformity (SEM), and coating adhesion.

-

Relevant News