How to Choose the Right Coating Machine for Battery Electrodes?

Upload Time:

Jun 26, 2025

In lithium battery production, the coating process plays a vital role in determining electrode quality. Two widely used coating methods are comma scraper coating and slot-die extrusion coating. Understanding their mechanisms, advantages, and suitable applications can help you select the optimal coating equipment for your materials and process needs.

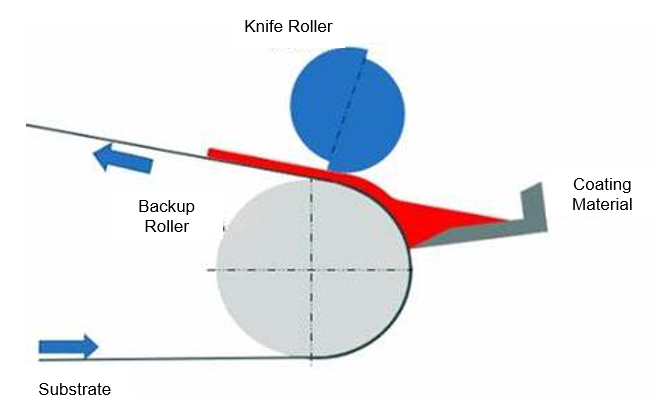

1. Comma Scraper Coating

(适用于高固含量 & 高粘度浆料 High Solid Content & High Viscosity Slurry)

In this method, the slurry directly contacts the moving substrate through a coating blade (scraper). The gap between the scraper and substrate determines the coating thickness. Excess slurry returns to the tank, and a uniform film forms on the substrate.

Key Features:

-

High coating force and precision

-

Excellent for high-viscosity and high-solid-content slurries

-

Suitable for thick coatings

-

Simple structure but requires fine blade adjustment

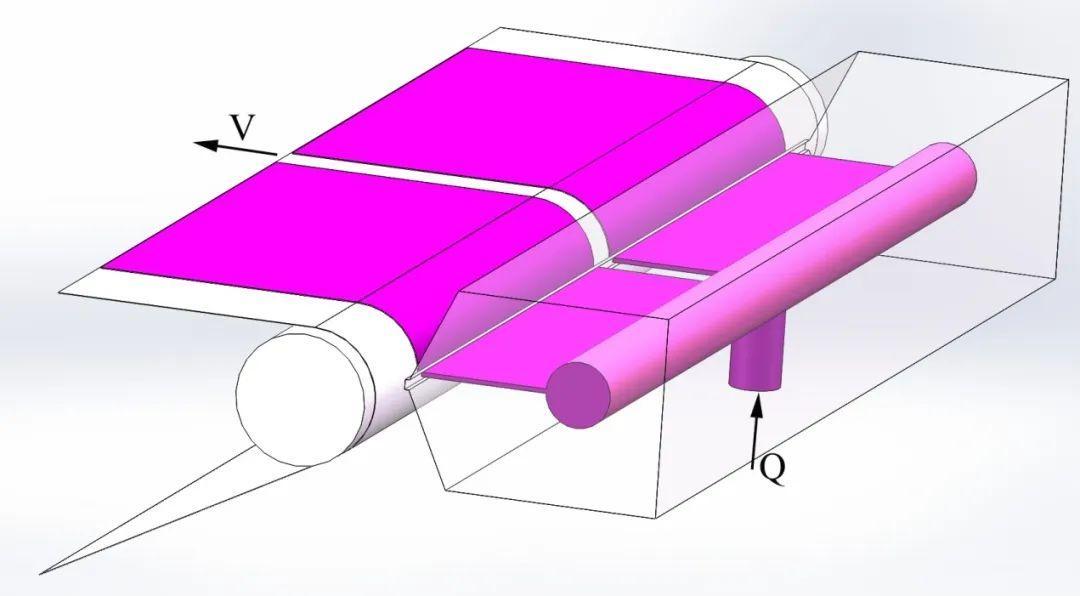

2. Slot-Die Extrusion Coating

(适用于多种浆料粘度与固含范围 Broad Material Compatibility)

This technique uses a slot-die head to extrude slurry under controlled pressure and flow rate. The slurry is dispensed through a slit, then lands evenly on the substrate via nip rollers.

Key Features:

-

Higher coating speed and precision

-

Consistent coating moisture and thickness uniformity

-

Sealed system reduces contamination risk

-

High slurry utilization rate

-

Ideal for multi-layer coatings

Which One Should You Choose?

| Criteria | Comma Scraper Coating | Slot-Die Coating |

|---|---|---|

| Slurry Viscosity | High | Wide Range |

| Solid Content | High | Medium to High |

| Coating Thickness | Thick | Adjustable |

| Uniformity | Moderate | Excellent |

| Equipment Cost | Lower | Higher |

| Application Scenario | R&D, pilot-scale, specific high-solid formulas | Mass production, multi-layer systems |

Expert Tip:

For cutting-edge lithium battery or supercapacitor production, slot-die coating is increasingly favored for its precision and efficiency—especially when handling next-gen slurry systems with tight uniformity requirements.

Relevant News